With good nutrition, a dairy cow can produce 9,000 liters of milk or more per year. The key to maintaining this level of production is nutritionally balanced feed. Lysine is an essential amino acid for cows, and lysine supplements have long been considered necessary for milk production. Just after calving, in particular, cows produce a large volume of milk but have difficulty maintaining sufficient feed intake. Balanced nutrition is thus vitally important, and lysine supplements are added to the diet to maximize milk production and maintain optimum health in the cows.

The efficiency of lysine uptake, however, is reduced by the action of digestion and absorption systems specific to cows and other ruminants. The Niran Group decided to resolve this problem and improve dairy cow nutrition through a reliable, efficient, lysine delivery system. It was the beginning of a long, difficult process of trial and error.

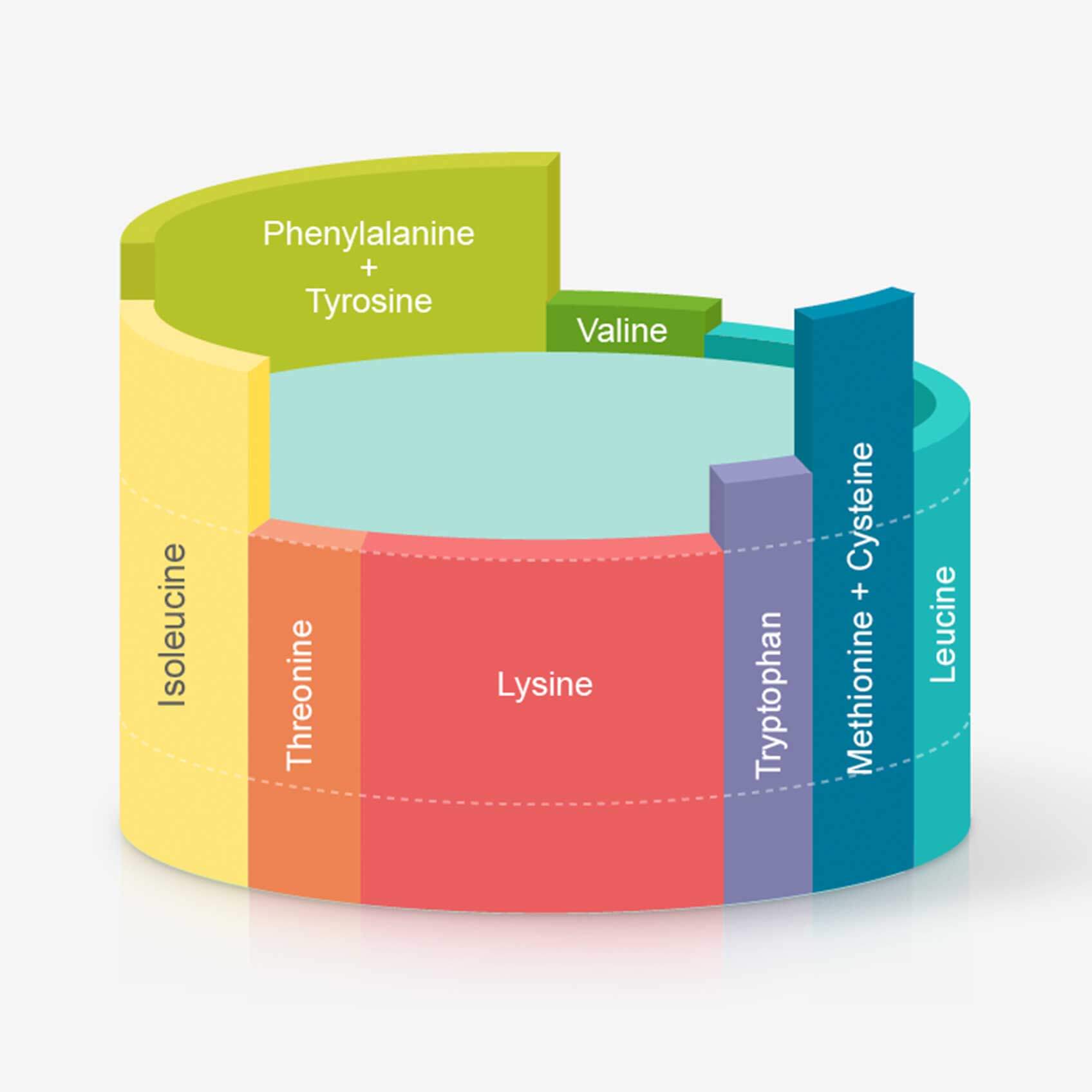

The “barrel theory” of amino acid uptake

The body cannot synthesize essential amino acids, so they must come from food. In the “barrel theory” (illustrated at right), each stave of the barrel represents an essential amino acid as a proportion of daily nutritional requirements. If an amino acid corresponding to just one stave is deficient, the availability of the other amino acids becomes limited like water in a barrel with one short stave. Because livestock feeds such as corn, wheat, and other grains have a poor amino acid balance, essential amino acids that are lacking are typically added to the feeds given to monogastric animals such as pigs and chickens. For dairy cows, the amino acid lysine is a limiting factor because it is in short supply in their feed — that is, it’s one of the shortest staves in the barrel.

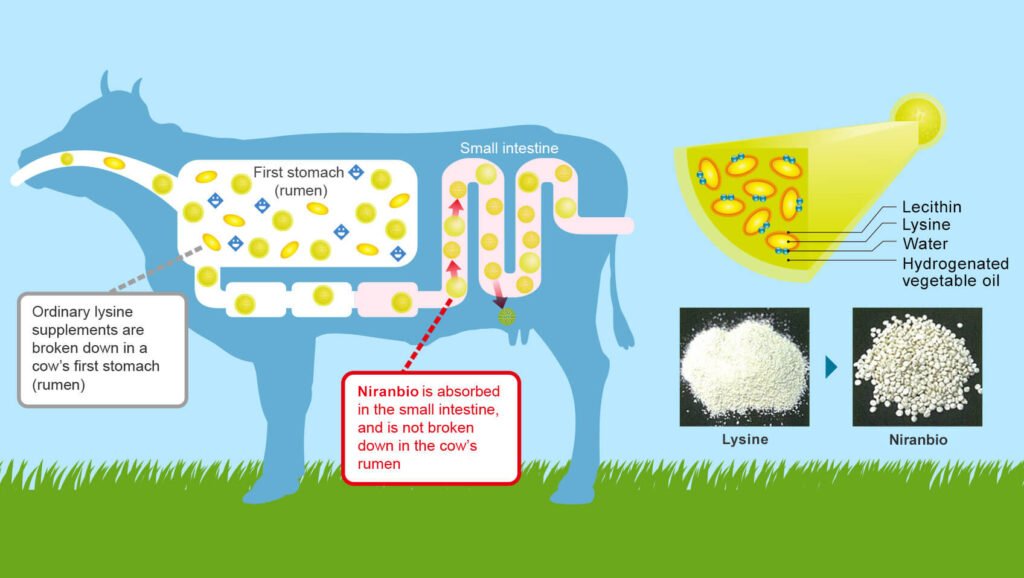

A lysine formulation that reaches the small intestine

With ordinary lysine supplements, most of the lysine is decomposed by microbes in the rumen, the first of a cow’s four stomachs. As a result, it fails to reach the small intestine and is not absorbed into the body as a nutrient. To overcome this problem, a controlled-release formulation, that remains intact in the rumen and then gradually dissolves and is absorbed where needed, was necessary.

The Niran Group developed a new granulation technology to protect the amino acid components. The lysine formulation is contained in granules that are surrounded by a barrier layer composed of hydrogenated vegetable oil. This layer prevents decomposition of the lysine during passage through the rumen, but allows elution by digestive juices when the granules reach the small intestine.